Engineered Stone - Ban in Western Australia - What you need to know.

The Recent Ban on Engineered Stone in Western Australia: What You Need to Know

Introduction

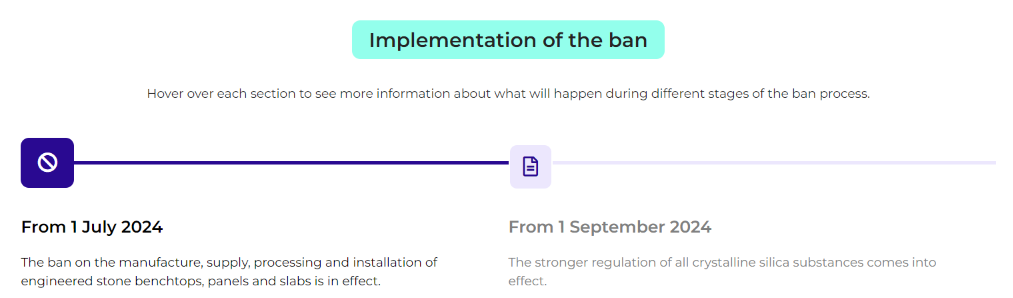

Western Australia has taken a significant step towards safeguarding the health of workers in the construction and manufacturing industries by announcing a ban on engineered stone. This move, which has garnered attention and support from various stakeholders, is aimed at reducing the risk of silicosis, a severe lung disease caused by inhaling crystalline silica dust. As this ban comes into effect 1st July 24, it is essential to understand the implications, reasons behind the decision, and what it means for the industry.

What is Engineered Stone?

Engineered stone, also known as quartz stone, is a popular material used in countertops, tiles, and various other building applications. It is manufactured by combining natural quartz with resins and pigments to create a durable and aesthetically pleasing product. However, the cutting, grinding, and polishing of engineered stone release fine silica dust particles, which pose significant health risks to workers.

The Health Risks

Silica dust is a known carcinogen, and prolonged exposure can lead to silicosis, a debilitating and potentially fatal lung disease. Symptoms include shortness of breath, persistent cough, and chest pain, which can progress to more severe respiratory issues. The rise in cases of silicosis among workers in the engineered stone industry has raised alarms, prompting calls for stricter regulations and protective measures.

What you need to know:

Dry cutting, trimming, drilling, sanding, grinding or polishing engineered stone without effective controls generates very high levels of silica dust. This respirable crystalline silica produced when inhaled will expose workers and others to levels of silica dust that would be expected to exceed the workplace exposure standard and is a serious health risk. A person conducting a business or undertaking (PCBU) must not direct or allow workers to undertake uncontrolled dry cutting or processing of engineered stone. The following methods can be used to reduce the risks of silica dust:

All workers who process engineered stone must also be provided with and wear respiratory protective equipment. Further guidance on how to effectively manage risks associated with working with engineered stone and, subsequently, minimise the incidence of respirable crystalline silica-related diseases, such as silicosis is available in the Managing the risks of respirable crystalline silica from engineered stone in the workplace: Code of practice.

Products excluded from the Ban.

The following products are currently excluded from the ban:

These changes will apply to all materials containing at least 1% crystalline silica, including engineered stone. In relation to engineered stone, the changes include:

Amendments to the model WHS Regulations that give effect to these changes from 1 September 2024 are available. More information will be coming soon.